Futura Line is based in the province of Caserta and it is specialized in the production of toilet paper, kitchen paper, industrial rolls, napkins and extra-soft handkerchiefs.

Thanks to its thirty years of experience in the world of Tissue, OCME has supplied an automatic palletizing solution specialized in handling products in the tissue sector, guaranteeing maximum efficiency, pallet stability and, thanks to the modular layout, providing a customized solution based on the customer's needs.

The complete end-of-line offered was able to manage with precision, speed and efficiency the different formats of the products made by Futura Line.

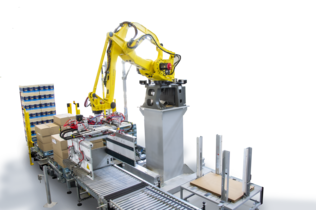

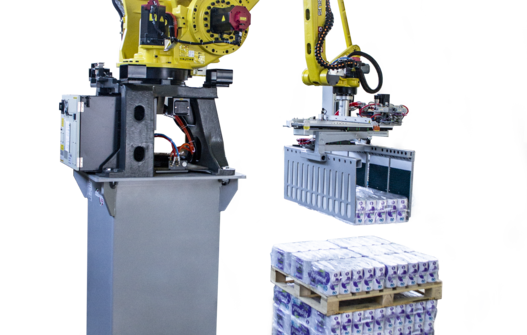

The palletizing phase has been entrusted to the robotic technology of the Pegasus models, solutions capable of managing various types of products and formats of four production lines with only three areas: one with a row gripper palletizing robot with bag overlay at infeed, capable of reaching 11 cycles per minute, and two palletizing islands with layer grippers. One of the two palletizing solutions with layer grippers is also capable of satisfying the product flow coming from two lines.

The difference between the solution with the layer gripping head and the so called "row gripping" is that the first one is able to handle an entire layer of product and deposit it on a pallet without deforming or stressing the product. The scheme that allows to have a compact layer with a stable pattern is managed by a robotic arm that moves or rotates the incoming products according to the pre-set format and pattern while maintaining the performaces and minimizing any possible shock or stress to the packs.

After the palletizing phase, two wrapping systems were provided in a compact and optimized space, in order to meet the production needs of the line and stabilization of the product on pallets.

The two stretch wrapping rotating ring, the Robopac Genesis Cube, are enriched by the "Top Inside" covering device, ideal for wrapping and stabilizing loads on single and overlaid pallets.

This system consists of covering the top of the pallet with a sheet of film that is later retained during the pallet's downward wrapping phase.

Moreover, the wrapping machines are equipped with a pre-stretch carriage with double external brushless motorization and with a shrinking device of the wrapping band; both are fundamental to realize and optimize the use of plastic material for a perfect stability of the pallet.

The stretch wrapping machines are equipped with the Cube Technology™. It allows to unwind the necessary amount of film, in the most effective position, with the most suitable containment force for the product, optimizing costs and consumption, and improving productivity.

The product is stabilized during the wrapping cycle in a safe way thanks to the pneumatic lift. It allows to wrap also the wooden pallet, stabilizing it with the product, while a presser blocks eventual oscillations of the pallet during the wrapping phase.

Packaging safety is also guaranteed by the stapling and sealing system of the wrapping film, which is done without reducing the wrapping band and without contact with the product.

With the product stabilized on pallets overlaid on the exit conveyors, we move on to the product handling phase in the warehouse.

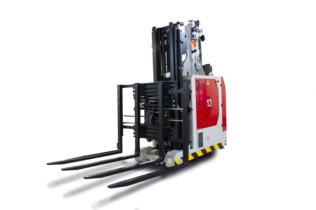

Transport to the wrapping areas is handled by a fleet of Auriga series laser-guided vehicles, four counterbalanced vehicles with forks that move up to two pallets simultaneously.

OCME's Auriga laser-guided vehicle offer both ease of implementation and operational flexibility and are equipped with a highly reliable guidance and correction system that does not require any intervention inside the plant.

By triangulating the laser signal on different reflector poles located inside the plant, the shuttles recognize the route and the correct location in real time and, by means of the LGV Supervisor software, they manage missions and priority criteria automatically.

In fact, the LGV Supervisor program is interconnected with other company devices - such as PCs, PLCs, databases, ERP systems - in order to define, monitor, forecast and store all the information related to the logistics system devices.

In this way, the vehicles move the stacks of empty pallets from the warehouse to the palletizing areas and the finished product from the production line to the base load, 24/7, automatically reloading in case of low production or line maintenance.

Thanks to OCME and Robopac technologies, Futura Line has been able to improve its efficiency and achieve important objectives: flexible and extremely fast palletizing, high product stability on pallets, automatic warehouse management and punctual product traceability in the warehouse.