Since 1793, Cedral Tassoni has been synonymous with quality, craftsmanship and tradition in the soft drinks sector. With more than two centuries of experience behind it, the company has been able to win over generations of consumers. This is thanks to iconic products —driven by high-impact advertising campaigns— and a sustained focus on the quality of raw materials and production processes. While remaining true to its roots, Tassoni continues to demonstrate remarkable capacity for innovation, dynamically adapting to the challenges of a continually evolving market.

As part of this ongoing development, two advanced technological solutions aimed at optimising the end-of-line phases have been successfully integrated in the historic factory in Salò, a small town overlooking Lake Garda. After a careful analysis of production requirements and industrial layout, the Aetna Group team identified the Robopac Helix 3 EVO and OCME Perseus as the most suitable solutions in terms of reliability, efficiency and level of automation.

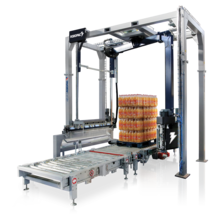

The Helix 3 EVO model is an automatic rotary arm wrapping machine for palletised loads, which is particularly suitable for sectors where high production rates are required. Thanks to the rotary arm technology, film deposit and load stabilisation take place while the pallet is stationary, thereby avoiding any risk of the load falling regardless of rotation speed, even for large pallets.

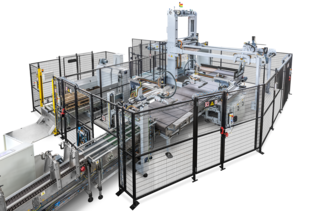

Perseus, a multi-sectoral palletising solution with 90° infeed, is able to guarantee high performance and considerable energy savings. It is characterised by reliability, versatility and the adoption of both low and high product infeed, with fixed or mobile pallets, as required.

A key factor in making the project a success was the customisation capability that characterises Aetna Group's operations: the two machines were adapted to the specific requirements of the Salò plant, with structural modifications designed to cope with the limited height of the facility. Thanks to this redesign, the solutions were seamlessly integrated into the existing production flow, in synergy with the rest of the line.

With this integration, the Salò plant's end-of-line phases were further enhanced, generating a positive impact on the company's overall production rate.

A success on both sides: on the one hand, Tassoni's experience and determination to find the most suitable solution for its requirements; on the other hand, Aetna Group's customised approach and its expertise in the beverage sector, an area which the company relies on heavily.