Partnering with the Group has enabled the perfect blend of high production rate, operational flexibility, and easy maintenance, fulfilling the requirements of a leading player in Spain’s industrial sector.

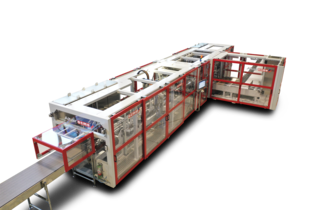

The glass line, installed at the LLeida plant in 2023, incorporates a range of high-performance solutions. The Gemini HT by OCME - a combined wrap-around and shrink-wrapping machine - is designed to process cartons and trays simultaneously (with or without film), delivering consistently high-quality packaging results. Perfectly suited for high-efficiency, high production rate plants, it can achieve speeds of up to 100 packs per minute. The integration of the Cygnus system by OCME allows the blank magazine infeed through robotic picking. The pallet simply needs to be placed on the conveyor, after which the entire process runs fully automatically, significantly reducing manual effort and improving operator safety. Pegasus by OCME, a robotic palletiser featuring a versatile gripping head, autonomously manages multi-code lines, while two Genesis Thunder by Robopac, a high-speed automatic rotary ring wrapping machine, ensure outstanding performance in material savings, load stabilisation, and waste reduction.

Installed in 2022, the can line was developed with the same focus on efficiency and automation that ensured the partnership’s continuation into the following year. The Altair HT, a wrap-around case packer, is a compact solution that combines flexibility, efficiency, and high magazine volume. Thanks to a system that enables a single machine to reach production speeds of up to 100 cartons per minute, Altair HT ranks among the fastest case packers in the world. Here too, the integration of Cygnus and Pegasus ensures safe and flexible pallet handling. Finally, two Genesis Thunder machines further demonstrate the effectiveness of the equipment and complete the end-of-line process by enhancing load stability and reducing waste.

Aetna Group and Mahou San Miguel continue to stand out as leading industrial players, bound by a successful partnership that has endured over the years. Both partners share a broad set of core values. These include user-friendly machine maintenance and cleaning, flexibility in business operations, and a highly responsive after-sales support team. The blend of speed, quality, and technical expertise has strengthened the relationship between the two players, while highlighting the Castel San Pietro (Bologna) group’s position as a leader in high-performance packaging solutions.